Gas flow meter applications

Thermal Mass Flow Meter

Compressed Air:-

Compressed air has wide range of applications across Industrial segments. Compressed air is considered to be the “fourth utility” after water, natural gas and electricity. When compared by cost per delivered unit of energy compressed air is costly other than three. There are six basic aspects of efficient compressed dry air system total demand, system storage, operational supply, output air quality, on demand distribution, and overall management. All six elements need to work together for the system to reach its extreme efficiency.

Accurately tracking the use of compressed air is must. By knowing exact air production or consumption rate using PCD Compressed air flow meters we can optimize complete systems, assure stable quality and also reduce energy losses.

Natural Gas:-

Natural gas is one of the cleanest and most useful forms of energy. It is combustible and burns more cleanly than some other energy sources helps strengthen its position as one of the most highly used energy sources. Most of industrial sector in today world uses natural gas as energy sources as it is one of the cheapest and most efficient sources of energy makes it easy to see why it is so commonly use. By using natural gas flow meter we can optimize the usage.

Natural gas has numerous uses in the metal, fertilizer, power generation, crockery, glass, oil mills, plastic, petroleum refining, chemical sector, food processing and paper industries. Common natural gas appliances used in Industries are furnace, kiln, boiler, dryer, hot air generation, thermo pack, natural gas fired gensets.

Bio Gas:-

Biogas is a renewable gaseous fuel which contains approximately 50-70% methane and 30-40% carbon dioxide. Biogas is produced as a by-product from the decomposition of anaerobic digesters and organic waste in landfills that municipal waste water and process agricultural waste. Biogas is the ideal fuel for combined heat and power or generation of electric power. Biogas can be used readily in all applications designed for natural gas such as direct combustion including absorption heating and cooling, space and water heating, cooking, drying, and gas turbines. It may also be used in fueling internal combustion engines and fuel cells for production of mechanical work or electricity. Through a catalytic chemical oxidation methanol production can be obtained by use of methane.

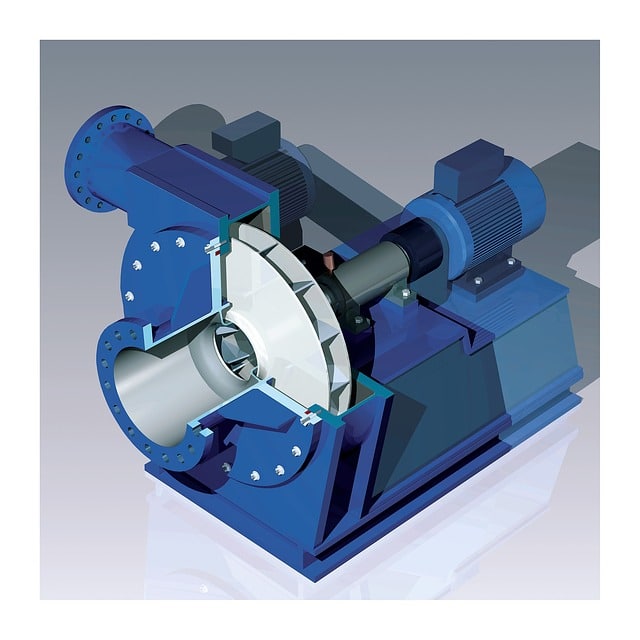

Bio Gas flow meters introduce by Process Control Devices (PCD). The device has been designed to be easy to install and safe whilst delivering the performance required in these applications. This flow meter is designed specifically to solve the especially challenges to flow metering in bioprocess generated methane.

LPG Gas:-

LPG stands for Liquified Petroleum Gas which consists of propane, butane and mixture liquified under ambient temperature and moderate pressure. It is used for heating and cooking purposes. LPG can be used in many applications in the industrial sector namely in process-heating, production of food, kilns, furnaces, powering industrial ovens, production of packing material as well as in powering forklift trucks in warehouses.

PCD LPG gas flow meters are used to measure the mass of LPG gas consumed in various process mentioned above. Flow meters that we offer are manufactured with the use of best quality components that impart strength and endurance. It provides accurate readings of the flow with an absolute ease. Our flow meter is sophisticated and work with utmost precision.

Flue Gas:-

Flue gases emits from many process industries such as petroleum, metals, chemical, food processing, paper plants, pharmaceutical, power plants and boilers.

Flue gases are the common name given to the mixed composition gases that are the by-product of a combustion process. A flue is typically a duct, stack, large pipe, chimney or other venting connected to a process system such as a furnace, boiler, steam generator, oven etc through which waste flue gases are emit from the combustion process.

Depending on the process mostly flue gases can consist of nitrogen, carbon dioxide, trace amounts of oxygen and water vapor and environmentally sensitive pollutants such as nitrogen oxide, carbon monoxide, sulfur oxides and other traces of gas.

Measuring the flow of flue gases for process control data reporting is often mandated by environmental and regional air quality regulations. PCD Insertion flow meters offer accurate and cost effective solutions to flue gas measurement.

Flare Gas:-

Gas flares are used in diverse activities including natural gas production and distribution, oil refineries, chemical plants, biogas, wastewater treatment and the steel industry. In these applications PCD thermal mass flow meters are ideal for measuring the gas flow.

Flare stacks are used to burn waste gases from Oil and Gas Production, gas processing facilities, tank batteries, dehydration facilities, tank farms and industrial plants. These flares frequently convert organic hydrocarbons and chemical to primarily water vapor and carbon dioxide.

There is frequent changes in flow rates, density, pressure and gas composition of flare gas which makes its measurement most difficult. PCD thermal mass flow meters have exhibit their ability to measure the low flow rates of normal flare conditions and also the high velocities found in upset conditions.

Landfill Gas:-

Landfill gas generates through disposal of large quantities of organic waste in landfill sites such as land voids, typically disused quarries, sand pits, gravel pits and open cast mine workings leads to a natural process of degradation caused by the bacteria contained within it. Landfills produce a mixture of approximetly methane (50%) and carbon dioxide (50%) with traces of nitrogen, oxygen and other gases. These gases are extracted from multiple wellheads and collected to a common header pipe through a network of pipes.

Accurate flow measurement of the landfill gas through the process provides the information about the amount of gas being extracted and provides proof of their carbon dioxide emissions for reporting to Environmental Regulatory Bodies

PCD Flow Meter provides mass flow measurement with its thermal mass dispersion sensor without need for additional pressure or temperature compensation or density calculating devices. Its insertion style makes it easy to install in existing piping without cutting the pipe hence minimizing interruption to plant operations..

Hydrogen (H2):-

Hydrogen gas is used in a various industries such as power plants, oil refineries, food, plastic and polymer manufacturing and has the need to accurately measure gas. It is mainly used as a circulating gas. It has very unique characteristics and requires a flow meter that has been calibrated considering operating parameters.

PCD offer in line mass flow meter specialty design to measure low flow hydrogen gas and is available in sizes as small as ¼” tubing up to larger line sizes. Our mass flow meter technology provides a 100:1 turndown with negligible pressure drop.

Methane (CH4):-

Methane is a one of the powerful greenhouse gas that remains in the atmosphere for over 10 years. It is approximately 21 times more effective at trapping heat in the atmosphere than that of carbon dioxide and is of growing environmental concern and it is a major concern of Greenhouse Gas reduction initiatives. Methane is a primary integral of natural gas and is an important energy source. Utilization of methane emissions can provide significant economic and environmental benefits.

PCD Thermal Mass Flow Meters helps in accurately measure the captured of gas emissions from landfills, including biogas and digester gas. Our flow meter is highly developed to be used in operating parameters of methane gas and work with utmost precision.

Argon (Ar):-

Argon is commonly employed as a blowing gas in steel manufacturing to avoid the formation of nitrates. Mass flow meters are commonly used to measure argon in steel production process. PCD offer inline thermal mass flow meter with inbuilt display to regulate the flow rate and to check the commutative gas flow.

It has a negligible pressure drop across the flow meter with high turn down ratio and is available in sizes as small as ¼” tubing up to larger line sizes.

Nitrogen (N2):-

Nitrogen gas is odorless, colorless gas and makes up approximately 78.09% by volume of the air we breathe. It is nonflammable gas and does not support combustion. Nitrogen gas is required in many processes of the pharmaceutical and chemical industry. There is multi usage of nitrogen gas in various industries sector such as metal manufacturing process, chemical, pharmaceutical, petroleum, fertilizer, rubber and plastic, food and beverage industry. Thermal flow meters directly measure the mass flow rate of gas with no need of temperature and pressure correction.

PCD Thermal Mass flow meter TMF Series offer rugged, leak proof construction, high turn down ratio of 100:1 with high accuracy, which makes our flow meter user demandable.

Oxygen (O2):-

Oxygen makes up important proportion of the atmosphere that is about 20.94 % by volume and 23 % by weight. It is colorless, odorless and is highly reactive. It reacts strongly with combustible materials releasing heat because of its oxidizing properties in the process. Oxygen gas has a low boiling point, -183 degree Celsius and it is around 1.1 times heavier than air.

Uses of oxygen in the industry are immense. Oxygen gas also known as the second largest industrially consumed gas. It has reactivity that it finds application in steel processing, welding and cutting of steel.

Steel industry is known as the huge consumer of commercially produced oxygen. For production of steel basic oxygen furnace uses oxygen in large proportion. There are many benefits of using oxygen in the industrial processes. The use of oxygen also helps to minimize the amount of fuel needed to make a given product. Oxygen is used with fuel gases like acetylene in flame hardening and flame straightening, gas welding, gas cutting and flame cleaning.

PCD TMF SERIES flow meters are needed to verify consumption, identify excessive usage of oxygen gas. PCD inline flow meter is excellent choice for measuring the gases, especially given their wide turndown and reproducibility.

Propane (C3H8):-

Propane is one of nature’s most versatile sources of energy. It is a flammable hydrocarbon gas liquefied through pressurization. Along with butane and mixtures of these gasses it is classified as LPG. In wide applications, the solution can be found in commercial grade propane furnaces and water heaters.

Measuring the flow rate of propane to the boiler it is often necessary for better combustion efficiency and to meet environmental requirements.

PCD Thermal Mass Flow Meters have negligible pressure drop and wide turndown to meet this requirement. PCD TMF series provides both easy-to-install in-line thermal flow meters and insertion thermal mass flow meters. Addition to that to reach difficult burner lines or locations with extreme radiant heat, PCD also offers a remote type flow meter, with up to 50 meters maximum lead length compensated cable transmission.

Carbon Dioxide (CO2):-

Carbon dioxide is an odorless, colorless gas that is stable at room temperature. In most of the industries carbon dioxide gas is used to produce chemicals and as feedstock. Carbon dioxide gas is also involved in the production of refrigeration systems, welding systems, water treatment processes and carbonated beverages. It also used in the metals industry as a soldering agent to enhance the hardness of casting molds.

PCD Mass Flow Meters are frequently used to measure and totalize the flow of carbon dioxide gas. The flow meter is considered an important part of the carbon credit verification process. PCD flow meter also provides information that the digestion process and the destruction equipment are operating properly.

Ammonia (NH3):-

Ammonia is mostly used as a fertilizer and coolant in industrial applications. Thermal mass flow meters can be used for ammonia measurement. Using thermal mass flow meters to measure ammonia flow does impose some difficulties. A major obstacle is to calibrate the flow meter for ammonia gas. Each flow meter has to be calibrated on a flow bench using the actual gas to obtain highest accuracy, yet due to safety concerns a direct calibration using ammonia is not practical. Thus it is calibrated using substitute gas by considering thermal gas properties of that gas

Ethane (C2H6O):-

Ethanol is produced from a complex process involving fermentation tanks and distillation. The cost of fossil fuels is continuously rising up and air pollution reduction regulations agencies become more stringent which further leads the production of ethanol fuel grows. Accurate gas flow measurements in various pipes and duct applications are challenged by deform flow profiles and swirls, changing of gas temperatures, installation costs, and accessibility for maintenance. Measuring gases emits from the process can provide beneficial information about process inefficiencies. Further, measurement and reporting may be mandated by air pollution regulations agencies. PCD thermal mass flow meters can be used in ethanol production to measure waste gases, fuel gas and air flow to enhance process efficiency and lessen pollution.

Sulfur Dioxide (SO2):-

Sulfur dioxide is a colorless gas that can be emit into the air through various manufacturing processes, especially through the combustion of coal for power generation. Since coal is not a pure carbon, most coal contains other chemicals including sulfur. When coal is burned, the sulfur combines with the oxygen in the combustion air to produce sulfur dioxide gas, which is emitted into the air through a plant’s stacks, if not detach by a scrubber.

PCD Insertion mass flow series offer volume measurement of SO2 gas emit form plant’s stack. Insertion flow meter offer easy installation, robust construction with advance electronic output of communication feature.