The amount of water used in industrial and residential buildings is determined by water flow meters. A municipal water delivery scheme provides water to households and businesses.

The flow concentrations of a section of the system may also be measured by using water metering at water supplies or in the water system. Flowmeters, the flow velocity of slurries, or fluids may be determined in closed pipes as well. The water flow velocity is calculated in the electronic or mechanical register of cubic meters (m3) or litres.

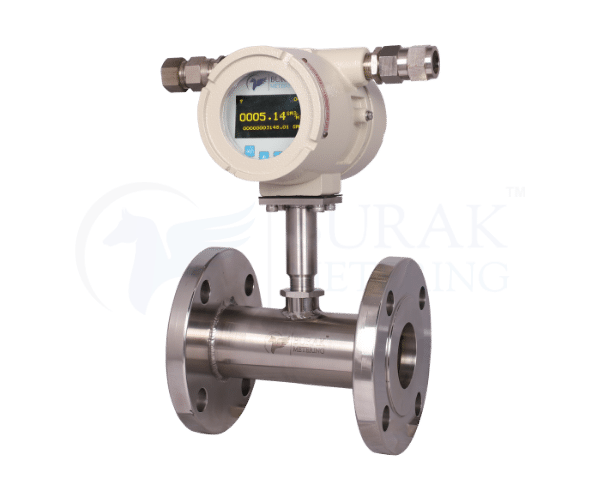

Meter water movement may be used to calculate hot, freezing, clean water, muddy, and slurry water. In the calculation of the water flow meter, two common methods are used: speed and flow meter displacement. A broad range of technologies is used in each form.

Sensors for paddlewheel: A cost-efficient and most widely employed water flow meter is the paddlewheel sensor. It may also be used for calculating water-like fluid flow speeds. Many sensors are marketed with paddlewheel fittings or with flow fittings. Like turbine meters, the inlet has a 10-pipe straight pipe diameter, and the outlet has a 5-pipe diameter. The paddlewheel sensor rotor is connected to the flow rate. It contacts a small cross-section of the river.

Flow Meter Optimistic Scrolling: This form of flow meter is used when a straight pipe is inaccessible as there will be too much turbidity in a paddlewheel sensor as a turbine flow meter. Viscous liquids also utilize positive displacement flow meters.

Flow meters of the magnet: This form of flow meter has no moving parts and is not used for polluted, conductive liquids or with wastewater applications. Displays are an essential feature of this form of flow meter and can be used to record data or to track remotely.

Meters of Ultrasound Flow: This flow meter is used for applications, including drainage, slurries, and other filthy fluids. Typically this form of water destroys traditional flow meters. The theory of the Ultrasonic Flowmeter is that frequency fluctuations arise as reflected by gas bubbles or suspended particulate matter in motion. The Doppler Effect is also known.

No organization will provide better goods than PCD – Process Control Devices if you are searching for ideal flow meters for your industry. To provide consumer loyalty, the organization is dedicated to creating good quality and creative flow control devices.

We at PCD – Process Control Devices have many forms of flux meters and switches to hold your desires in mind. The business delivers the best market standards with a full range of flow meters and management equipment.

Conclusion: We at PCD – Process Control Devices ensure world-class calibration capabilities to include advanced temperature flow meters and fluid calibrations. The flow meters of the business track the flow of cooling in industrial applications to guarantee protection for all.

Want to Learn More : Types of Flow Meters Used in Industry

Recent Comments